Tensile Solutions

Conical Tension Structure

Hyper or Anticlastic Structure

Parallel Arch or Barrel Vault Structure

Hyper or Anticlastic Structure

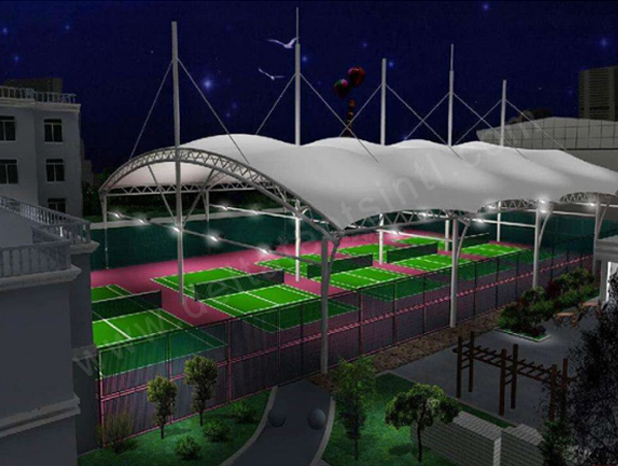

Tensile Membrane

Our company Delta tents & Tensile Shades offer a wide range of Tensile Membrane. As we are Historically inspired by some of the first man-made shelters—such as the black tents first developed using camel leather by the nomads of the Sahara Desert, Saudi Arabia, and Iran, as well as the structures used by Native American tribes—tensile structures offer a range of positive benefits compared to other structural models.

Tensile structure is the term usually used to refer to the construction of roofs using a membrane held in place on steel cables. Their main characteristics are the way in which they work under stress tensile, their ease of pre-fabrication, their ability to cover large spans, and their malleability. This structural system calls for a small amount of material thanks to the use of thin canvases, which when stretched using steel cables, create surfaces capable of overcoming the forces imposed upon them. Structurally, the system is formalized by combining three elements: membranes, rigid structures such as pole and masts, and cables.

The membranes of PVC-coated polyester fibers have greater ease in factory production and installation; lower cost; and medium durability—around 10 years. PTFE-coated glass fiber membranes have superior durability-around 30 years; and greater resistance to the elements (sun, rain, and winds); however, they require skilled labor.

Some of the other features are as follows:

- Height at rear 12’

- Height at front 9’

- Sides at rear 9’

- Sides at front 6’

- Width 12’

- Length 18’

- Olive Drab cotton canvas walls and roof.

- Has a long front dining room section.

- Tent comes complete with stakes, side and internal solid wood poles, cross beams, screen mesh, and wrapping panel.

- Canvas Only and Complete with Poles.

Tensile Membrane Structure

Fabric Detail of Tensile

PVC coated polyester fabric

PVC stands for Polyvinyl Chloride and is applied on the fabric as a paste. It improves the thermal properties of the yarn, provide enhanced surface aspects and helps in cleaning. For fire resistance a secondary coat of plasticizes are applied such as phtalates, phosphates or esters. PVC can be used for imparting color and light stability. The PVC coat is implanted with stabilizing molecules to achieve thermal, oxidation and UV protection.

PTFE Coated Glass

Silicon Coated Glass Fabric

ETFE Foils

Design Process of Tensile

The methodology includes the way work is carried out. First, the process of design is explained, which comes in three main steps as follows:

- Form-Finding Form finding can be defined in the following ways: “Form finding is the iterative process through which a designer arrives at the best possible shape that the membrane can adopt under the applied initial force or pre-stress”. The process of form finding basically depends on the boundary conditions and initial force which decide the shape of the structure.

- Static and Dynamic equilibrium for designing structures it essential to consider different load combinations taking into account the magnitude and direction. The curvature which may obtain by form finding is taken and analysis is done to check the permissible deflections. The dynamic analysis evaluates the relation between the fluctuating load applied and the structural geometry. As wind is the critical factor, the main objective is to perform dynamic analysis is to check the stability of membrane under wind load cases.

- Patterning it is the process by which the pre-stressed 3D membrane (the form found structure) is transferred into a 2D pattern for the structure. At this stage the generated shape has prestress applied and the cutting pattern therefore has to be smaller than the final shape, as illustrated below.

Structural Modeling & Analysis

In this work, software used are AutoCAD, Dlubal RFEM5, Form Finder and Mpanel. To study the concept of geometry of fabric (form Finding), Initial load distribution and Deformation of the fabric membrane, simple analysis of membrane structure Hyper and Cone is performed in Dlubal RFEM5, with two different type of fabric membranes with different properties (named as PTFE Type A & Type B). In both models Initial Force of 1 KN/m & 2 KN/m is applied to observe the variation in Form as well as strains. Again the boundary conditions of membrane as Fixed and Free are considered to observe variation in results. MODEL -1: A Hyper of dimension 10 m x 10 m x 3 m is considered, in which Initial Force of 1 KN/m & 2 KN/m is applied and analyzed. MODEL -2:

A Rectangular Cone of 10 m x 10 m x 3 m is considered, in which boundary conditions as Fixed & Free is considered and analyzed.